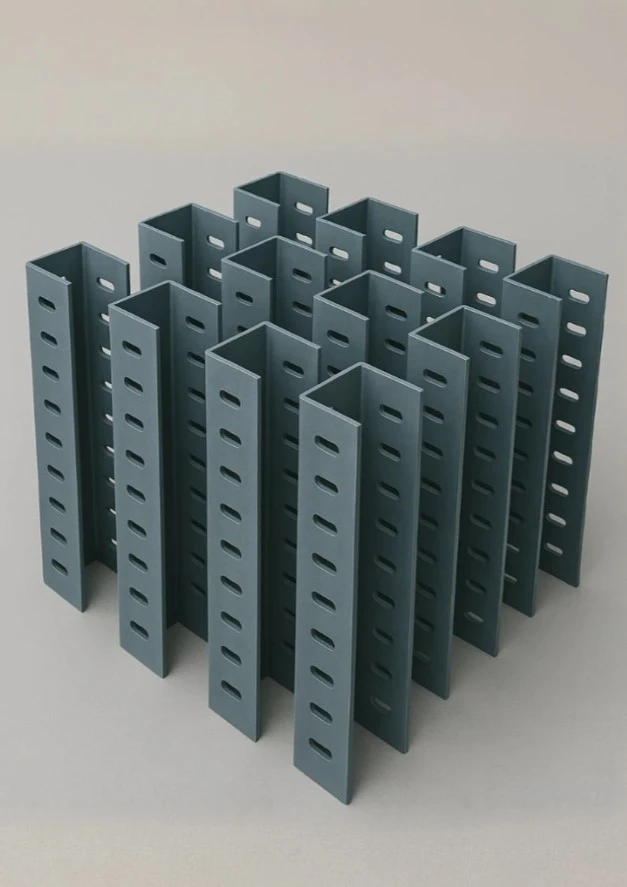

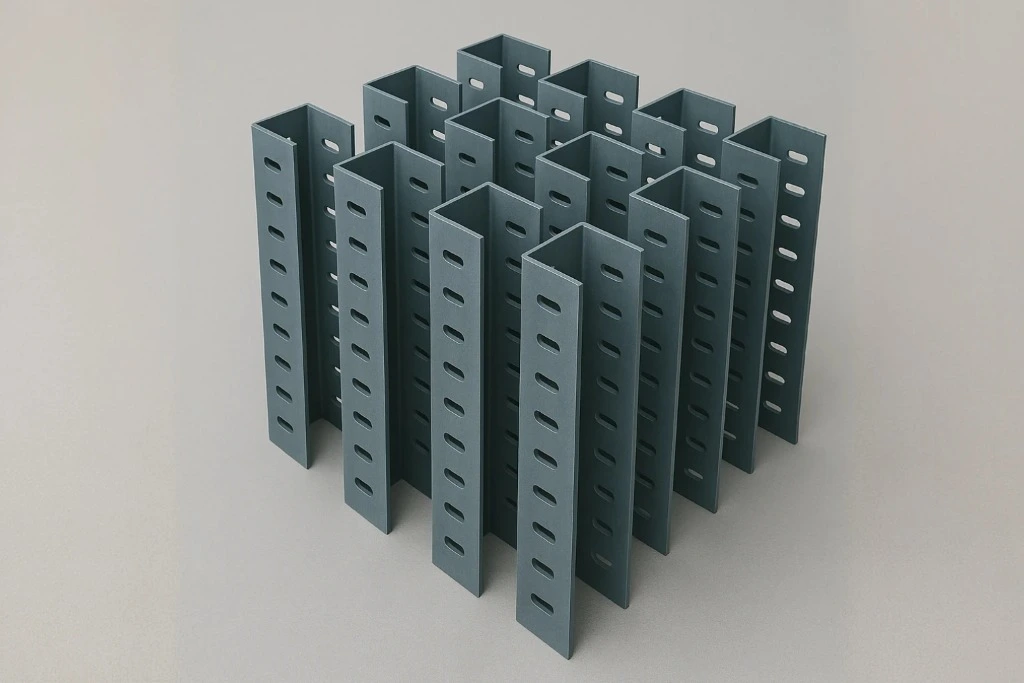

Wall channels are U-shaped or C-shaped steel profiles used extensively in the construction and reinforcement of walls, partitions, and structural frameworks. Typically made from galvanized or mild steel, these channels are known for their strength, durability, and resistance to corrosion. Available in various sizes and thicknesses, wall channels provide essential support in both load-bearing and non-load-bearing applications, making them a vital component in modern building systems.

In drywall and partition systems, wall channels function as horizontal tracks that secure vertical metal studs, enabling the precise and stable installation of gypsum or fiber cement boards. Their standardized shape and dimensions allow for quick assembly and alignment, which simplifies installation and reduces labor time on-site. They are also used in ceilings and bulkhead framing to provide edge support and structural definition.

Wall channels are U-shaped or C-shaped steel profiles used extensively in the construction and reinforcement of walls, partitions, and structural frameworks. Typically made from galvanized or mild steel, these channels are known for their strength, durability, and resistance to corrosion. Available in various sizes and thicknesses, wall channels provide essential support in both load-bearing and non-load-bearing applications, making them a vital component in modern building systems.

In drywall and partition systems, wall channels function as horizontal tracks that secure vertical metal studs, enabling the precise and stable installation of gypsum or fiber cement boards. Their standardized shape and dimensions allow for quick assembly and alignment, which simplifies installation and reduces labor time on-site. They are also used in ceilings and bulkhead framing to provide edge support and structural definition.

Beyond interior applications, wall channels play a significant role in reinforced masonry and concrete structures. They are often used to guide and support joint reinforcement rebars across large wall surfaces, increasing structural integrity and helping prevent cracking due to thermal or seismic stresses. In concrete formwork systems, wall channels are used to align panels, stabilize frameworks, and maintain consistent wall thickness throughout the casting process.

Due to their versatility, wall channels are also integrated into facade systems, curtain walls, and cladding installations, acting as secure mounting tracks for exterior panels and finishes. With their ability to combine structural precision, corrosion resistance, and ease of installation, wall channels are a preferred choice for engineers, architects, and contractors seeking reliable and cost-effective framing and reinforcement solutions.

Beyond interior applications, wall channels play a significant role in reinforced masonry and concrete structures. They are often used to guide and support joint reinforcement rebars across large wall surfaces, increasing structural integrity and helping prevent cracking due to thermal or seismic stresses. In concrete formwork systems, wall channels are used to align panels, stabilize frameworks, and maintain consistent wall thickness throughout the casting process.

Due to their versatility, wall channels are also integrated into facade systems, curtain walls, and cladding installations, acting as secure mounting tracks for exterior panels and finishes. With their ability to combine structural precision, corrosion resistance, and ease of installation, wall channels are a preferred choice for engineers, architects, and contractors seeking reliable and cost-effective framing and reinforcement solutions.